Portable indoor growth units utilising closed-loop hydroponics and artificial lighting are of interest for office spaces, classrooms and laboratories. The ability to grow small amounts of microgreens, herbs or salad indoors is beneficial for educational, research and personal well-being purposes.

In this project, CultinovaEDGE™ technology was utilised to realise a fully integrated control system for an indoor growing unit. Using a recycling flood-&-drain hydroponic system split over three levels, with multi-spectral LED lighting and temperature control, the demonstrator unit enabled the hyper-local production of small volumes of crops under tightly controlled conditions.

The unit was novel in that parameters critical to plant health, such as lighting conditions, irrigation and fertigation, and temperature are controlled automatically for the crop of choice, from germination through to harvest. The ability to choose a 'recipe' for the plant of choice simplifies the growing process, but also allows for variation of parameters where optimisation of growth conditions is required.

Working in close cooperation with a supplier of supplementary LED lighting and custom high-performance hydroponic systems, we realised a fully integrated control system with cloud connectivity for a portable indoor growing system.

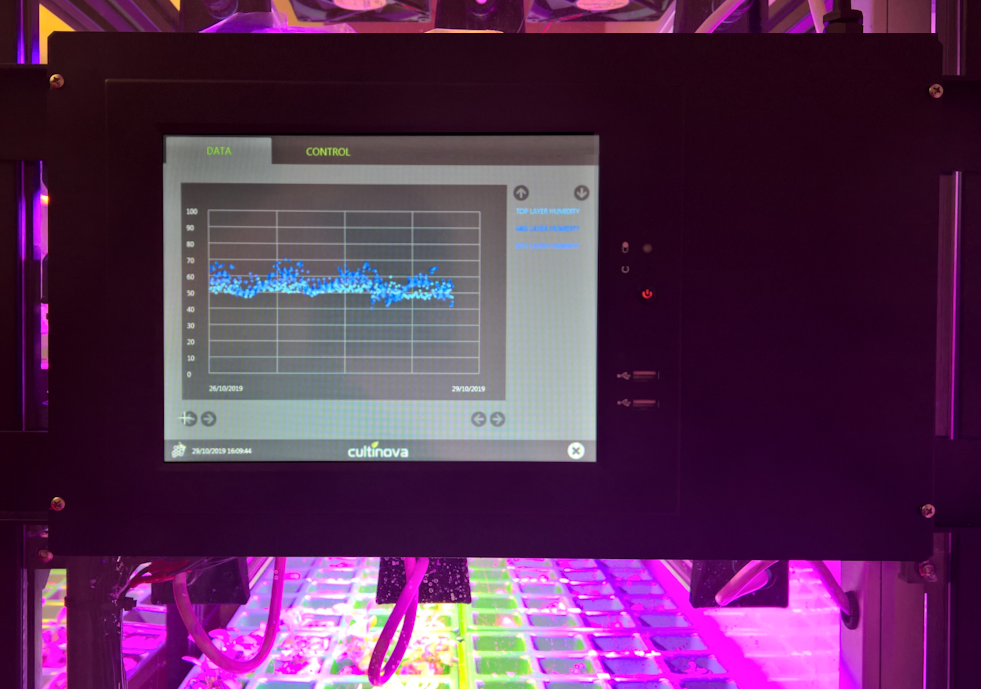

Multi-spectrum lighting control, irrigation, nutrient delivery and temperature control were all undertaken using CultinovaEDGE™ technology, all via a touch screen controller running Cultinova sensing and control software.

Our standard software offering was further developed for this project to allow the automatic download of growth control parameters in the form of recipes from a cloud-based storage system. The cloud-connectivity also enabled the upload of sensor data in real-time, allowing for subsequent remote monitoring and control of the growth unit via a mobile app provided by the project end-client.

Novel aspects of the design of the growth unit lay in temperature control and the ability to utilise a small volume close-loop hydroponic system, as required by such a compact unit. Temperature control was achieved though a combination of natural convection, forced ventilation and the residual heat provided by the LED lighting. Through optimisation, it was possible to ensure the required high degree of temperature control through the growth unit for plant health and to prevent the build-up of excess moisture.

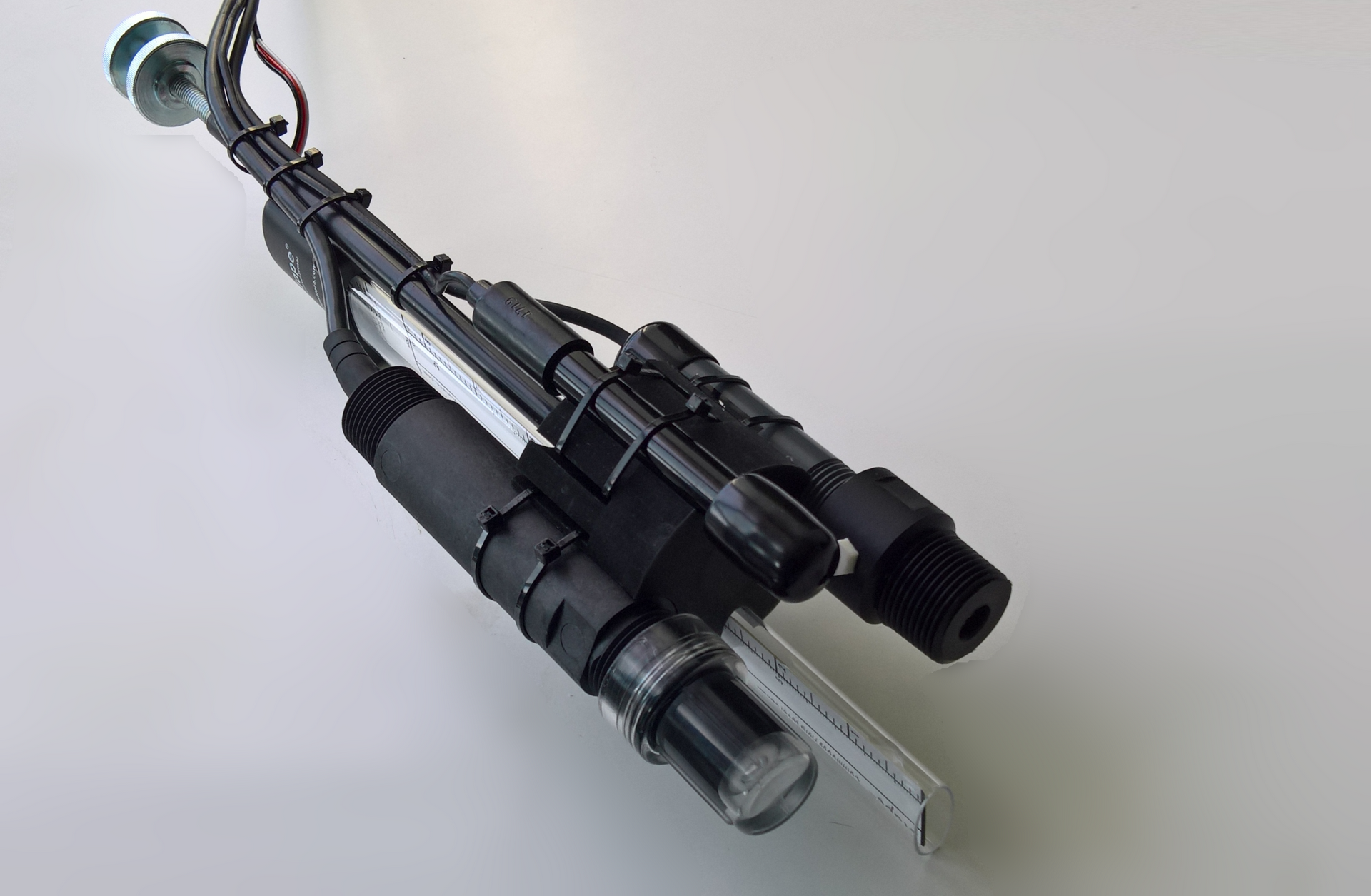

A small volume flood-&-drain system was enabled through the separate irrigation of each level of the growth unit using a system of valves and flow meters. This enabled a 66% reduction in the size of the storage tank required to store the irrigant and nutrient feed compared to similar systems. The compact nature of the hydroponic system also required the manufacture of a bespoke sensor cluster, this being undertaken by one of our manufacturing partners.

c/o Experior Micro Technologies Ltd

Sadler Bridge Studios

Derby

DE1 3NT

United Kingdom

c/o Experior Microtech GmbH

Fürstenrieder Straße 279a

81377

Munich

Germany