As part of the research activities within the Growing Knowledge Workgroup, Hochschule Osnabrück (HSO) undertook the construction of a climate controlled grow room and a separate mobile container farm to investigate light, temperature and nutrient interactions on plant performance using multiple flood-&-drain hydroponic systems.

The objective was not only to research the relationships between lighting, nutrients and environmental conditions on plant characteristics, but also provide a test environment for the evaluation various types of horticultural LED lighting and novel growth structures such as 3D plastic-matrix growing media.

A specific challenge for HSO was to make best use of the available space in both environments and this was achieved by splitting them into zones each with its own growth racks, closed-loop hydroponic system and supplementary lighting system.

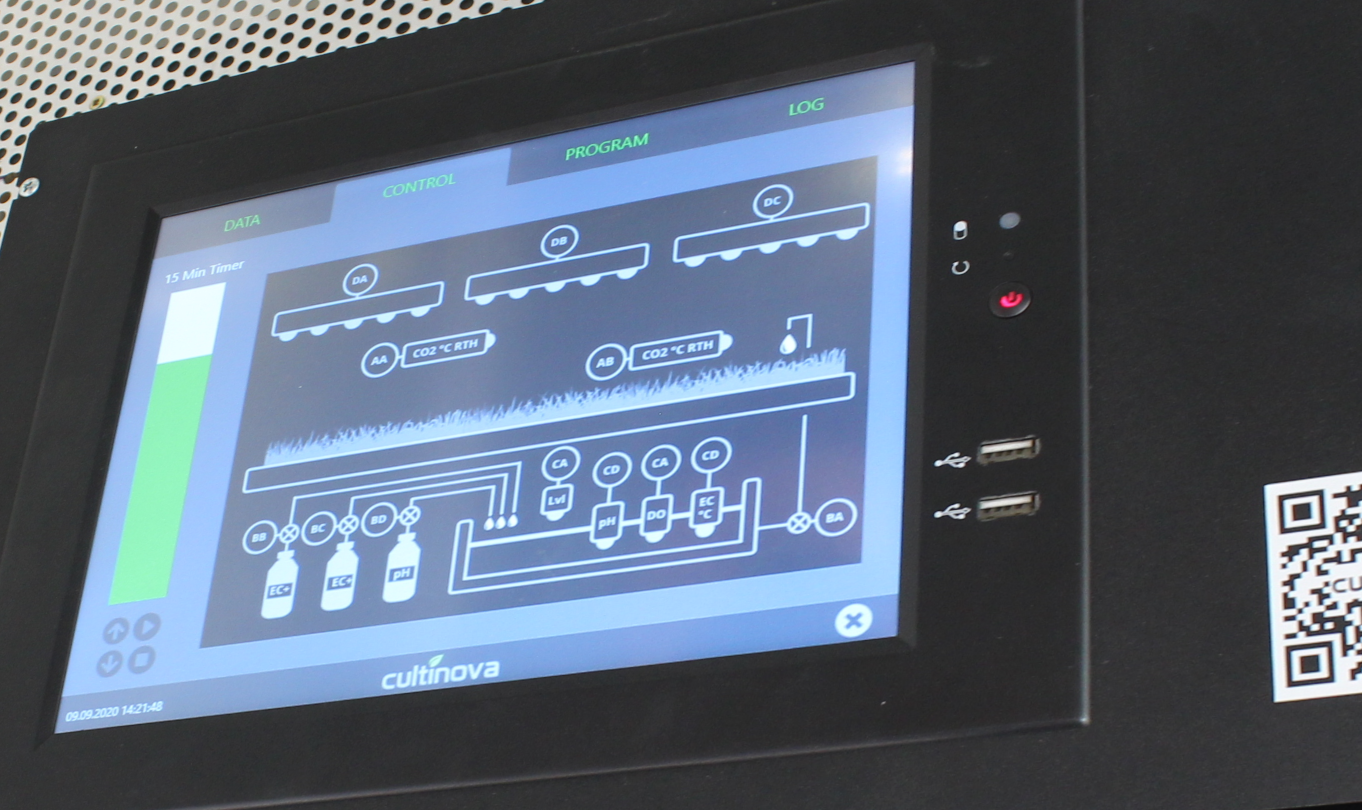

Within each zone, HSO had the requirement to undertake multi-point environmental monitoring (CO2, relative humidity and temperature), irrigation control, nutrient monitoring (pH and EC) and lighting control (spectral intensity).

Due to its modular nature and high degree of configurability, CultinovaEDGE™ technology was used to undertake sensing and control functionality in both the grow room and container farm.

Based upon in-depth discussions with HSO regarding the experimental goals of the growroom and container farm, Cultinova defined a system specification detailing the required measurement and control parameters for each test-environment. A total of 48 separate measurement and control channels were required for environmental, irrigation, nutrient and lighting control covering the various zones, each containing a separate hydroponic flood-&-drain system and multi-spectral luminaires from various manufacturers.

Further optimisation of the growroom and container farm by HSO led to further modification of the system specification. Cultinova developed a final system specification, including details of the electrical, mechanical requirements and planning for system installation.

Based upon the final system specification, Cultinova configured a matrix of CultinovaEDGE™ sensing and control modules, procured associated sensors and hardware and assembled the system for bench testing and verification prior to installation. Luminaires from the lighting manufacturers defined by HSO were also tested for compatibility with the Cultinova control hardware to prove system operational reliability.

Cultinova provided on-site support to HSO electricians and technicians during system installation. This also provided the opportunity to commission and test of each sensing and control channel and evaluate system performance.

Subsequently, a period of testing and further system optimisation was undertaken where Cultinova provided HSO with system-level support, data access and control parameter optimisation via remote login to the on-site CultinovaEDGE™ main control unit.

Once system commissioning was complete and the growth environments were proven to operate reliably, the growth room and container farm were used by students and researchers for a broad spectrum of experiments on a range of model crops as part of the HSO Growing Knowledge research program.

c/o Experior Micro Technologies Ltd

Sadler Bridge Studios

Derby

DE1 3NT

United Kingdom

c/o Experior Microtech GmbH

Fürstenrieder Straße 279a

81377

Munich

Germany