As part of their new research greenhouse development, Liverpool John Moores University required a supplementary lighting system to enable investigation of the effects of wavelength and intensity on plant morphology.

A key requirement was the ability to dynamically modify spectral intensity in response to the level of external sunlight in real-time. Additionally, the lighting system would act as a testbed for the WL range of high-performance light emitting diode (LEDs) from Würth Elektronik.

Working closely with a bespoke lighting manufacturer, we utilised CultinovaEDGE™ technology to implement an eight zone LED supplementary lighting system with dynamic intensity control to produce constant light intensities across multiple crop growth areas.

The main challenge within this project was to realise a multi-spectral LED supplementary lighting system that would maintain a constant level of light intensity at crop level irrespective of the sunlight level external to the glasshouse.

At low levels of available sunlight, the light intensity of the LED supplementary lighting should be increased to achieve a user definable Photosynthetic Photon Flux Density (PPFD) at a particular point in the crop canopy. At higher levels of available sunlight, the intensity of the LEDs would be reduced to maintain the required PPFD level.

To achieve this, CultinovaEDGE™ technology was used to measure the available sunlight entering the greenhouse using a precision Photosynthetically Active Radiation (PAR) sensor. This measurement was used to regulate the intensity of eight pairs of custom LED luminaires independently via an algorithm which utilised a precision PPFD calibration for the selected luminaires.

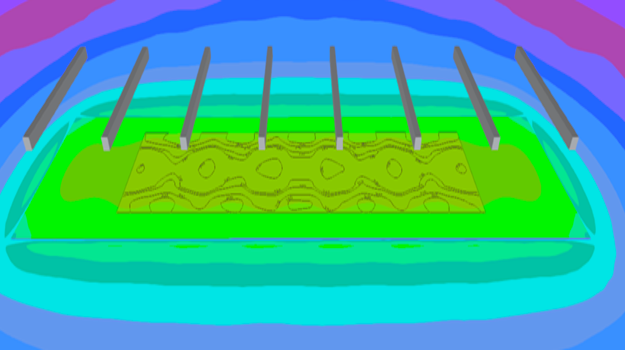

Working together with a manufacturer of horticultural LED lighting, 3D optical simulations of the glasshouse space were undertaken to define LED density and distribution pattern in order to achieve the required light intensity. Based upon the simulated results, custom LED luminaires were manufactured using 3 types of LED diode chip with the required spectral outputs.

Once the manufacture of the luminaires was complete, the complete lighting system was bench tested to verify the basic operation. The system was subsequently installed in the glasshouse by an electrical subcontractor and tested over a two-day period where PPFD measurements using a portable optical spectrometer were compared to the previously simulated results and good levels of correlation found.

Cultinova provided operational support and training of the lighting system operation over a six month period, with additional fine tuning of the dynamic lighting intensity control algorithm.

Thereafter, the system was utilised in a wide range of experiments on strawberry, basil and wheat crops by students and researchers.

c/o Experior Micro Technologies Ltd

Sadler Bridge Studios

Derby

DE1 3NT

United Kingdom

c/o Experior Microtech GmbH

Fürstenrieder Straße 279a

81377

Munich

Germany