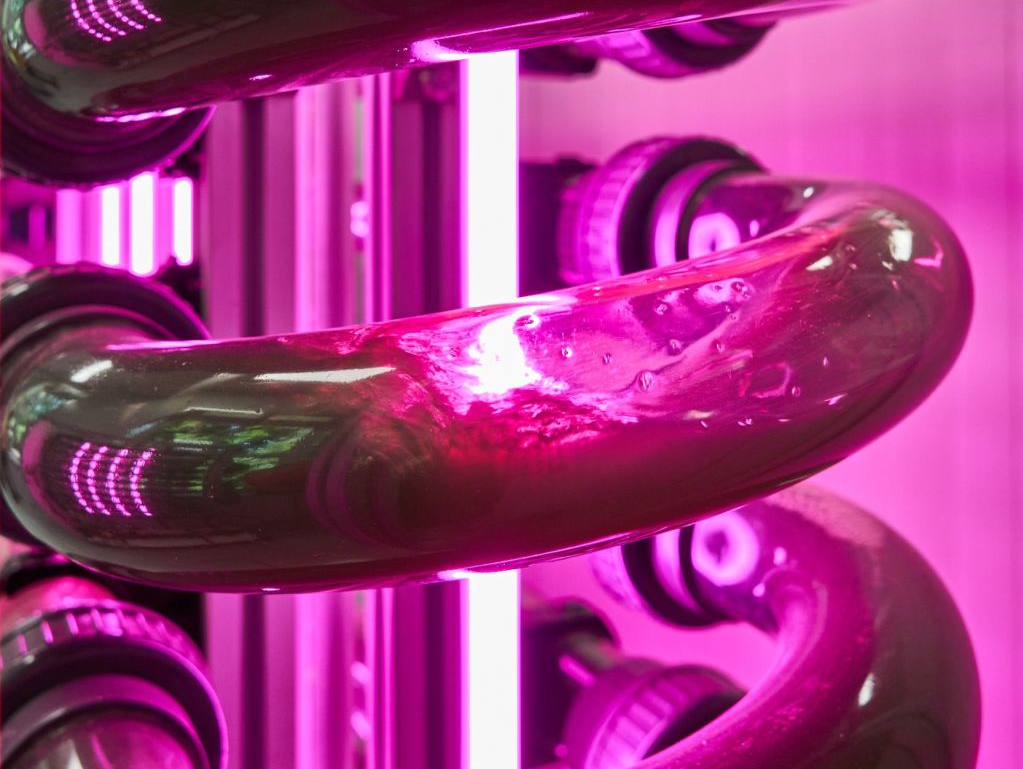

Bioreactors can be used for cultivating macroalgae biomass for carbon fixation and the production of plant-based protein and typically consist of clear-wall containers or pipes through which a liquid medium in which algae grow is circulated.

The liquid medium is exposed to heat and light which cause the algae to multiply, after which the algae are removed by filtration for further processing. The efficiency of the growth process is defined by the amount of energy required in terms of heat and light input to achieve a certain algae biomass.

In this project, CultinovaEDGE™ hardware was utilised to improve the energy efficiency of bioreactors for algae production by optimising incident light spectral intensity through the use of supplementary LED lighting.

To further increase the efficiency of the system, a novel heat recovery system was developed where waste heat energy from the supplementary LED lighting was used to maintain the temperature of the liquid medium at its optimum value, effectively replacing a heater that would be normally used for this purpose.

The utilised small-scale bioreactor showed a 12% increase in algae biomass production for a 16% reduction in energy use, compared to a standard system, demonstrating the potential of this approach for energy and cost savings in large-scale commercial bioreactors for algae production.

Working in close cooperation with a supplier of supplementary LED lighting for horticulture and a manufacturer of commercial bioreactors, CultinovaEDGE™ technology was utilised to realise a lighting and heat recovery control system for improving energy use efficiency in algae production.

High performance water cooled multi-spectral LED lighting was installed on the bioreactor and Cultinova software and hardware used to control and optimise the intensity of the emitted spectrum over four separate light-spectrum channels. The relative intensities of the applied light spectrum were optimised for different phases of the algae growth cycle.

The temperature of the coolant exiting the lighting system was measured with 0.25 degree centigrade accuracy and used to feed a heat exchanger via system of valves, also controlled by Cultinova hardware, for heating the liquid medium to the optimum temperature for algae biomass growth.

The temperature of the liquid medium was also measured at the output of the bioreactor in order to provide an accurate picture of the efficiency of the complete system.

Multiple growth-runs were used to optimise the operation of the lighting and heat recovery system and resulted in an improvement in the level of energy use efficiency to make the approach attractive for use in commercial algae production systems.

c/o Experior Micro Technologies Ltd

Sadler Bridge Studios

Derby

DE1 3NT

United Kingdom

c/o Experior Microtech GmbH

Fürstenrieder Straße 279a

81377

Munich

Germany